-

- Lighter than carbon fiber

- No flying fibers – Does not micro fiber when ground

- No discomfort or itchy sensation on your skin which is often common when working with carbon fiber

- Better cohesiveness with resin compared to carbon fiber

- The resin soaks through the fiber braid easier than carbon fiber braid resulting in less resin per volume of the braid which means lighter socket

- More cost effective than carbon fiber

- Provides great fatigue strength for the socket

- Tested in socket form under ISO guidelines for patients up to 300 lbs

-

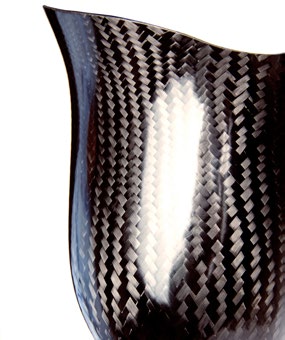

This fabric is extremely tightly woven and is commonly used in aerospace and other high quality applications. Meets MIL-C-9084C, Type III. Our carbon braid is sold by the pound from the manufacturer. Yield is based on a feet-per-pound ratio because of its tendency to elongate significantly. Most other carbon is pulled off of a spool and cut at its stretched length, dramatically affecting yield. At Fabtech, we weigh our carbon so our customer is guaranteed to get what they are paying for.

This fabric is extremely tightly woven and is commonly used in aerospace and other high quality applications. Meets MIL-C-9084C, Type III. Our carbon braid is sold by the pound from the manufacturer. Yield is based on a feet-per-pound ratio because of its tendency to elongate significantly. Most other carbon is pulled off of a spool and cut at its stretched length, dramatically affecting yield. At Fabtech, we weigh our carbon so our customer is guaranteed to get what they are paying for.